High Speed

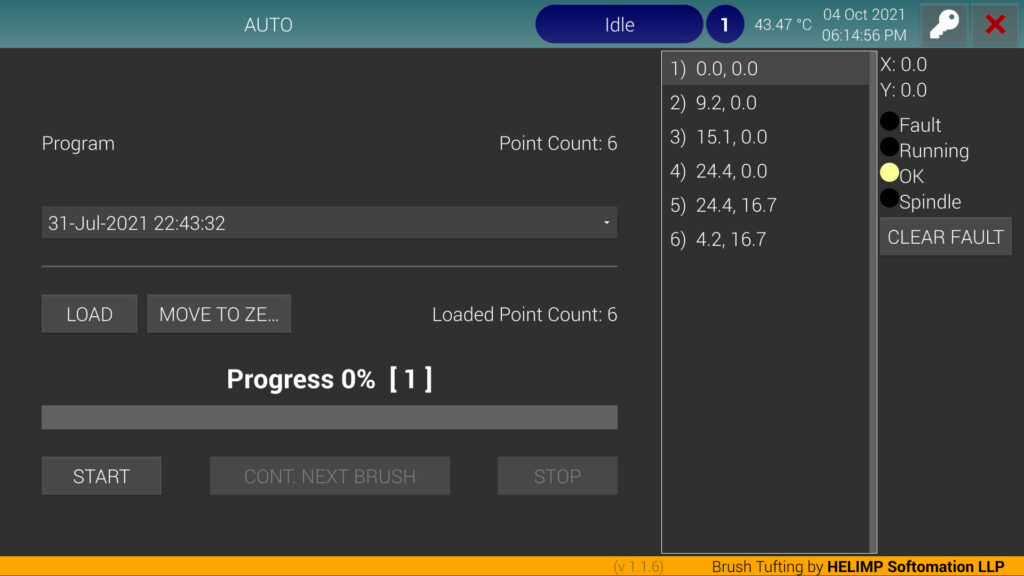

A customer machine can punch more around 250 tuffing points at an average distance of 20mm. Our real-time controller can sense the tuffing shaft position in milliseconds to perform precise brush movements.

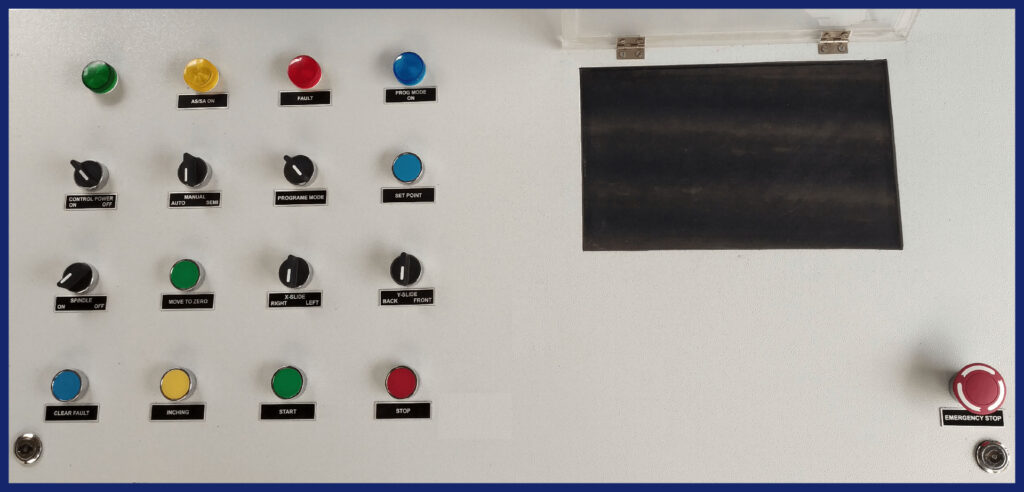

High speed Control solution for retrofit any manual brush tufting machines. We provide full control solution including electrical control-panel and HMI. Our controller unit is truly industrial proven solution for high-speed mission critical applications like brush tufting.

Brush Tufting

Advanced brush tuffing technology with precision control and high-speed performance for industrial applications.

A customer machine can punch more around 250 tuffing points at an average distance of 20mm. Our real-time controller can sense the tuffing shaft position in milliseconds to perform precise brush movements.

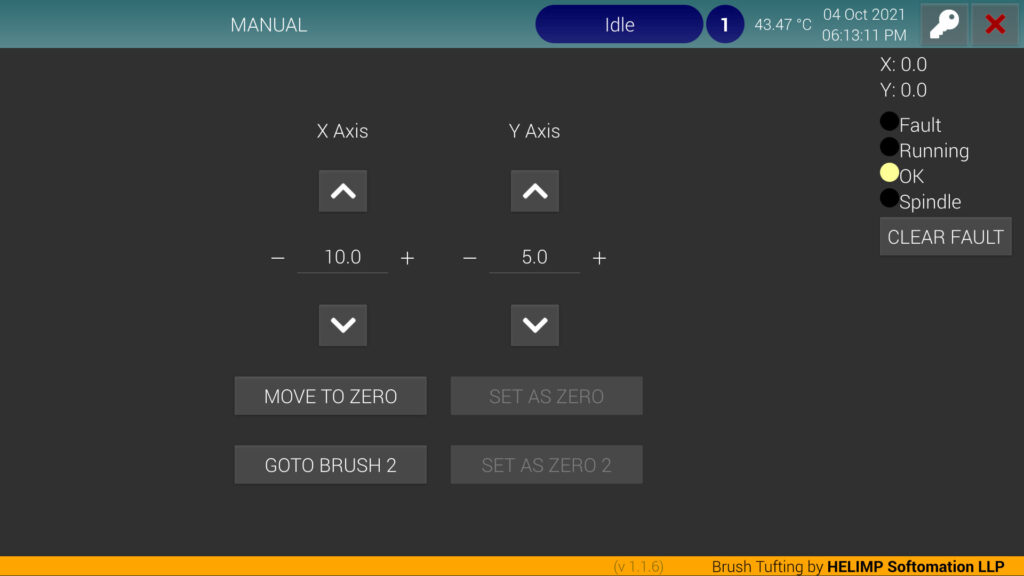

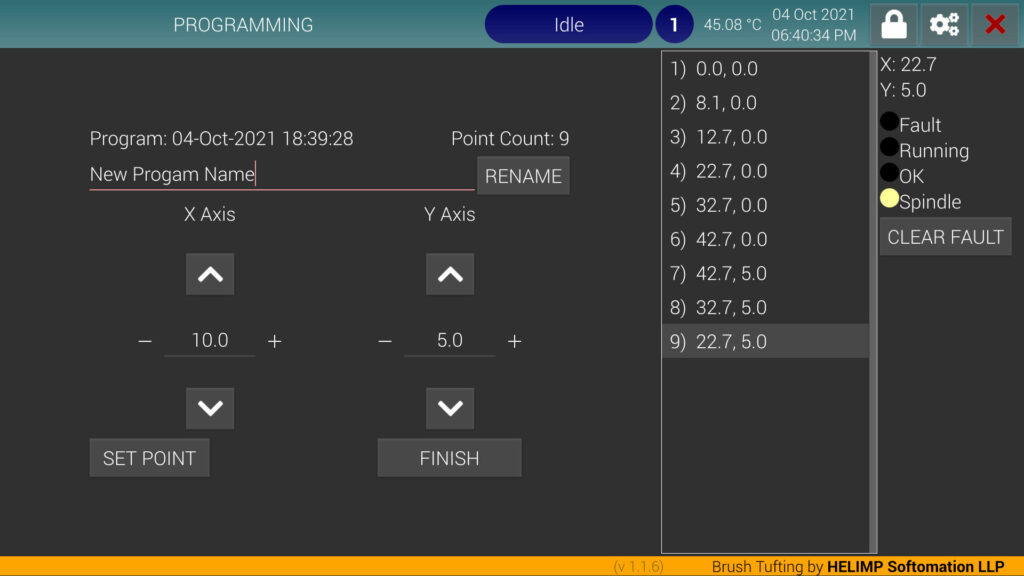

Touch Screen interface provides the best user experience. Operators can control the machine via control panel or software as per convenience.

The controller checks all safety interlocks before any motorized motion. Wiring is handled by professionals ensuring maximum safety.

Integrated servo motor motion control ensures accurate and consistent tuffing point punching every time.

Dual micro-controller subsystem handles both time-critical motion control and high-quality graphical interface on the touch display.

Easy-to-use operational panel allows operators to manage multiple machines efficiently. One-go execution performs complete tuffing automatically.

11″ Touch Screen

Servo Motion control (Can handle various makes like, Siemens, Schneider, Etc…)

Using Proximity Sensers

230VAC / 50Hz

1Phase / 3Phase depending on the servo selection

Overcurrent/Overload protection by MCB/MPCB

Master panel fan for overall control panel box

Dedicated controller fan for the best system performance