Customised Industrial Automation

Transform your operations with customised industrial automation solutions designed to boost efficiency, reduce downtime, and streamline production. From smart control systems to process optimisation, we tailor automation to fit your unique business needs.

Your Requirements Transform into Custom Automation Systems

Custom automation streamlines industrial processes. It enhances companies’ manufacturing capabilities, making them either partially or completely automated and ensures each manufacturing function is tailored to the user’s exact needs.

At Helimp Softomation, we steer clear of one-size-fits-all solutions. To make certain efficient and scalable manufacturing processes, we develop custom systems that include seamless automation process design, skilled engineering and state-of-the-art equipment—all of which we tailor to accommodate each client’s specifications.

The results of transitioning from manual to automated processes are – Custom automation solutions lead to higher-quality production, more extensive yields and lower manufacturing costs in the long term.

But we’ll get to the advantages of custom automation. First, let’s dive into the custom automation.

Your Requirements Transform into Custom Automation Systems

Custom automation streamlines industrial processes. It enhances companies’ manufacturing capabilities, making them either partially or completely automated and ensures each manufacturing function is tailored to the user’s exact needs.

At Helimp Softomation, we steer clear of one-size-fits-all solutions. To make certain efficient and scalable manufacturing processes, we develop custom systems that include seamless automation process design, skilled engineering and state-of-the-art equipment—all of which we tailor to accommodate each client’s specifications.

The results of transitioning from manual to automated processes are – Custom automation solutions lead to higher-quality production, more extensive yields and lower manufacturing costs in the long term.

But we’ll get to the advantages of custom automation. First, let’s dive into the custom automation.

Customized Industrial Automation Benefits

Customization at a lower cost

With custom automation, manufacturers can meet all their internal requirements while creating the exact solutions they desire. Machinery and equipment can be programmed to meet precise strength, durability, size and other requirements. This translates to complete customization for less money.

Increased uptime & safety

Automation solutions reduce points of failure, lowering downtime and eliminating operator mistakes. Custom solutions also protect labourers by allowing machines to take over risky tasks, reducing lost manpower due to accidents.

Improved process optimization & accuracy

Automation gives manufacturers insights into their processes, ensuring quality and international compliance. Machines handle repetitive tasks with precision, boosting accuracy and efficiency across operations.

Greater efficiency & production versatility

Machines excel at multitasking and can manage multiple aspects of production simultaneously. From high-volume to low-volume, adaptive automation supports flexibility, higher throughput, and tailored manufacturing.

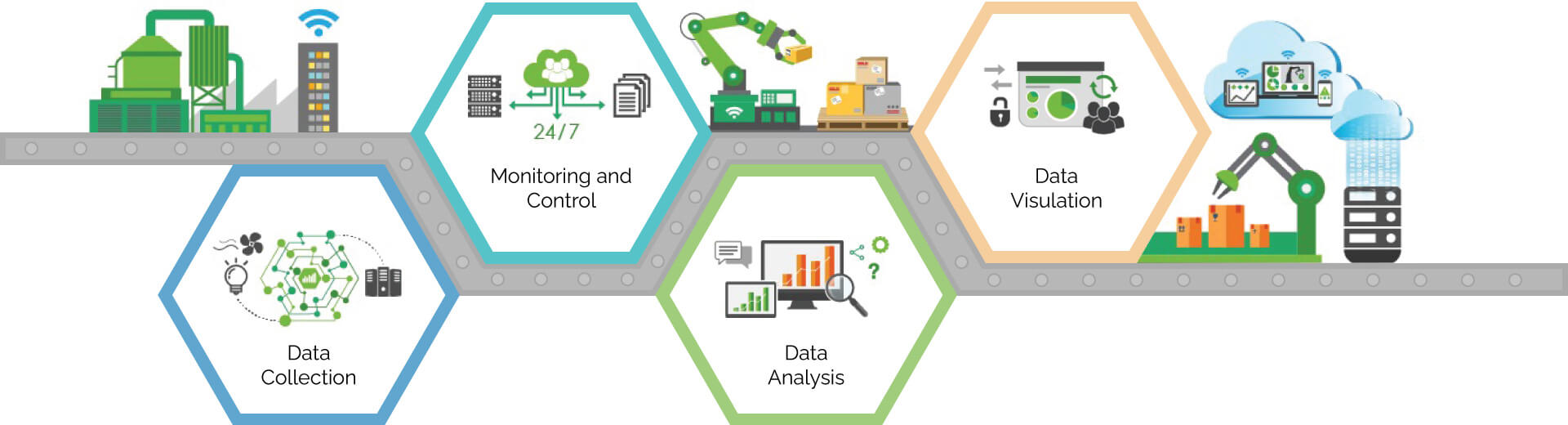

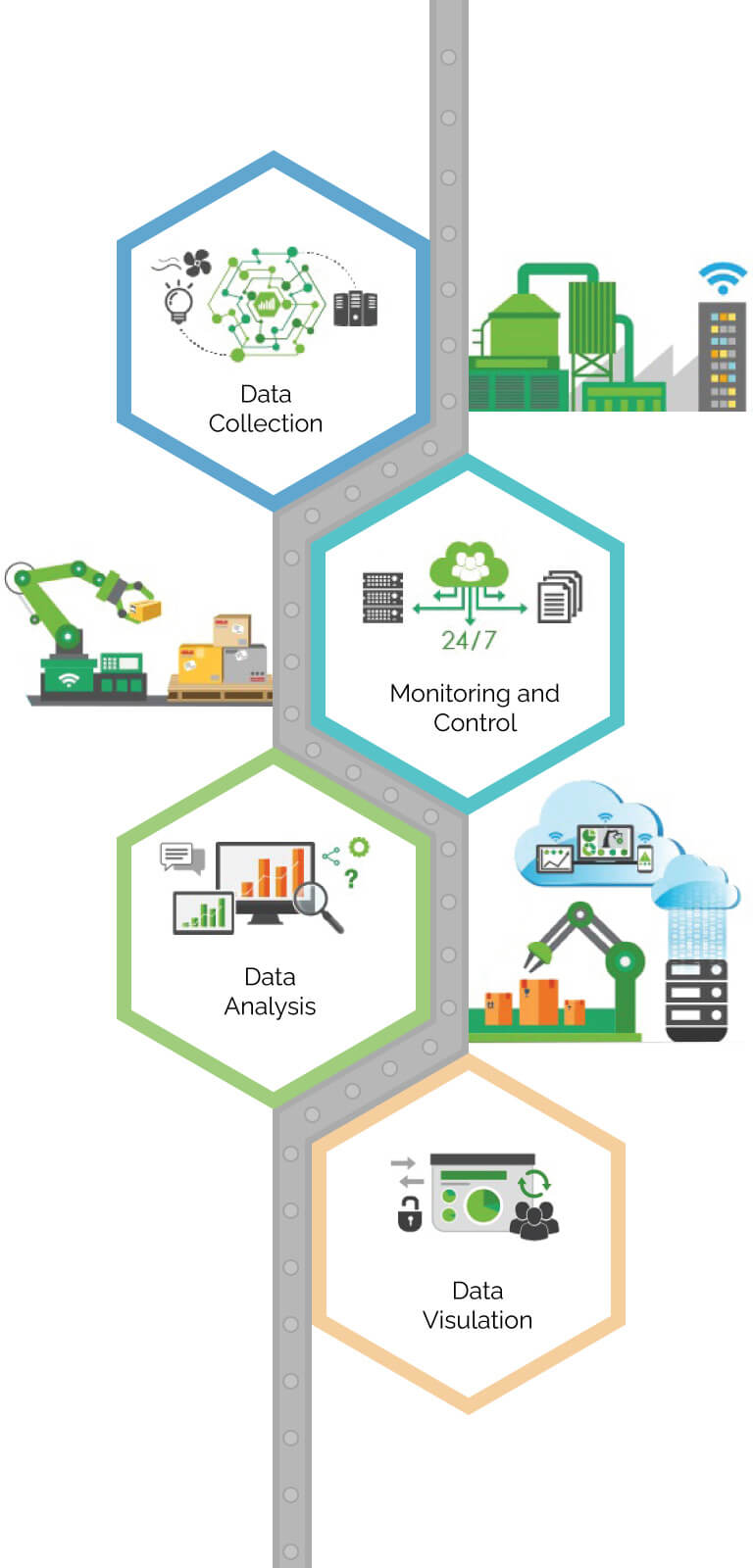

Automation Solutions

- Custom automation helps to streamline industrial processes by enhancing your company’s manufacturing capabilities. Custom machine automation allows your firm to tailor each manufacturing function to the end users’ specific needs. Custom automation can be either fully automated or semi-automated, depending on the needs of the particular job. Here is what each type entails:

- Fully automated solutions feed parts into and take them out of machines without any operator intervention, so there are no manual steps involved in the process.

- Semi-automated solutions require manual loading and unloading of parts in the machines and operators must manually activate the processes, usually by pushing a button. The amount of manual intervention needed varies from system to system and ranges from minimal to extensive.

Different Type of Automation Machines

Assembly Machine

Assembly machine Drive automation systems and production lines. They are highly efficient and have complete turnkey capabilities.

Inspection Machine

Gauge parts for quality, assembly completeness and dimensional accuracy, which guarantees that each part is in the correct shape and size, with no missing components.

Integrated Process Machine

More complex and are required for combining multiple automation processes. These machines can accommodate several different tasks, including orientation and labelling.

Testing Machine

Fulfil several testing requirements, including leak, flow and function tests.

Industries We Serve

Industrial Automation Solutions